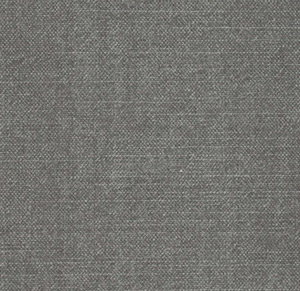

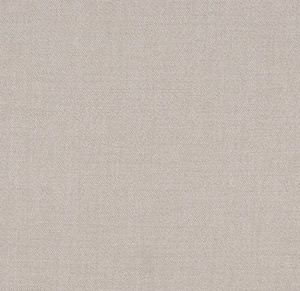

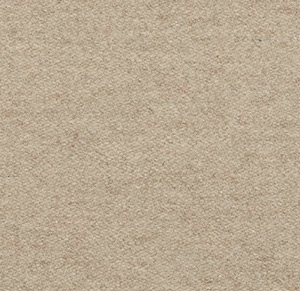

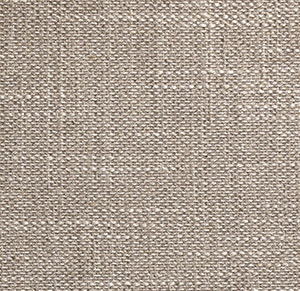

For years, the Furninova team of buyers and designers has created a range of fabrics that will complement our collection of sofas, armchairs, and beds perfectly. We continuously update our upholstery collection to be one of the best in the market.

Furninova offers about 40-50 different fabrics to choose from, and each fabric range has 4-7 different colors. This provides our customers with a wide choice.

Our goal is to put sustainability at the forefront of our development processes and create collections that reduce the impact on the environment without compromising quality or design. Each year, our aim is to increase the range of sustainable alternatives in our collection.

Pricing

We always strive to find the best quality fabrics at a reasonable price. Our fabrics are divided into three different price groups A, B, and C. A is the most affordable price group and C the most expensive. Groups are formed only by price, which means that A category fabrics are just as good as C category fabrics, but in B and C fabric groups additional value can be found in qualities such as Efficiency and Easy Care.

Testing Methods

We indicate three different values on all our hangings so that the customer can find the most suitable one. Martindale, pilling and light fastness tests are performed according to international standard.

Knowing the different methods explained below makes it easier to choose the fabric most appropriate for a specific client. For example, if a sofa or chair is intended to be placed by large windows, it is good to pay attention to its lightfastness. If the sofa is intended for a large family with children and pets, you need to additionally check if it has a lot and Martindale. Hair and outer fibers often cause pilling.

Martindale (wear cycle)

Martindale is a test that is done to check the durability of the fabric weave. The selected fabric is spread on a small disk, and then pressed with a certain weight against another piece of standard fabric. These two are rubbed against each other until two threads have broken or there are clearly visible changes in the tested fabric. When changes occur, the Martindale machine shows the value of how much rubbing was needed before the test was stopped. To qualify as furniture fabric, you must reach 15,000 rubs.

Pilling

The pilling test is performed almost like the Martindale test, the difference being that the selected fabric is rubbed against itself, not against another standard fabric. Then the device is set to rub before it stops, 3000 or 5000 rubs. When the machine stops, the fabric is evaluated by a laboratory person and compared to standard images to assess how much pilling it has. The scale ranges from 1 to 5, where 1 means a lot of pilling and 5 means that no changes have occurred during the test.

Lightfastness

In the lightfastness test, the selected fabric is placed in a device that is set so that the fabric is exposed to a certain type of light for a certain time. The fabric is then assessed by comparing it to a blue fabric scale that has been exposed at the same time as your fabric. The blue scale will yield 8 different appearances, where the first number is faded and number 8 has not changed at all. With indoor upholstery fabrics, the values are usually from 4-6. The best values 7 and 8 are set almost only on fabrics used outdoors.

TYPES OF FABRICS:

ACRYLIC

ACRYLIC

Acrylic is a synthetic fiber. It is particularly lightfast and moderately resistant to wear. Acrylic fabrics tend to pill, which often increases if they are mixed with other materials.

COTTON

COTTON

Cotton is a natural material and plant fiber. Cotton fabric is robust and very resistant to wear, so it works very well as furniture upholstery. This fiber can usually be washed and dried at high temperatures without disintegrating. It means that it has a great tendency to pill and shrink. Always observe the care instructions of the relevant fabric.

POLYESTER AND NYLON

POLYESTER AND NYLON

Polyester, as well as nylon fibers, are synthetic fibers that are suitable for use in furniture, which has worn heavily due to their irregularity. They have good color fastness and are easy to clean. Some velvet fabrics change color when light hits from different angles. This is a feature of the fabric and should not be considered a defect but rather an added bonus.

WOOL

WOOL

Wool is perfectly suitable for upholstering furniture, it is a natural material that is both resistant to wear and dirt and is also elastic. Its elasticity makes it less prone to pilling. Initially, there may be a slight compression on the wool surface. This is completely normal and in no way reflects the quality of wool upholstery.

VISCOSE

VISCOSE

Viscose is a less durable fiber, primarily used in furniture fabrics along with other more durable fibers, and then mainly to create a beautiful glossy or soft surface. Polypropylene is a synthetic fiber with excellent wear resistance, color and lightfastness, and it is easy to clean and maintain.

TYPES OF LEATHER:

Aniline and Semi-Aniline

Aniline and Semi-Aniline

Aniline leather is the highest quality leather. Pure aniline is processed with transparent, soluble dyes, preserving the natural leather surface so that all the animal's pores, scars, and footprints remain visible. This is the purest and most luxurious leather that money can buy. Soft and elastic to the touch, it has a rustic, textured look, and each hide is unique, like a fingerprint. Over time, aniline leather develops the rich patina that leather connoisseurs so desire. Unlike most other materials, this leather only gets better with age. This means that the patina can be an advantage or a disadvantage depending on what you are looking for. The minimal processing of this leather makes it more prone to stains and scratches, and it usually requires more care than other types of leather. Only 5% of all leather available on the market today is suitable for aniline leather. If you want your leather to age beautifully, it must be treated with designated leather care products. It should be done about 3 or 4 times a year.

Semi-aniline leather is aniline leather that has been dyed through and treated with an additional protective layer to increase its resistance to stains. The natural marks found on aniline leather can sometimes be found on semi-aniline leather. This leather is usually comfortable and provides good air permeability. Semi-aniline leather is less cold in winter, less sticky in summer, and more resistant to stains and scratches. This makes it more user-friendly than true aniline and more suitable for households with pets and children.

Nubuck and Corrected Leather

Nubuck and Corrected Leather

Nubuck is lightly sanded, through-dyed aniline leather with open pores. Nubuck is a living leather that breathes and absorbs moisture, fluids, and natural fats. The appearance can vary depending on the hide, for example, with texture and color and insect bites, scars, and scratches. These variations are characteristic of real leather, proving that the leather is real. During use, the leather acquires character and patina, making it more beautiful as it ages. Our nubuck is treated to make it more resistant to leaks and stains.

Corrected leather is leather made from the upper layer of leather, where the outer layer is sanded. It is done to remove various marks, such as insect bites, barbed wire cuts, scratches and other stains. Before the protective coating is applied, the leather is sanded or polished, and an artificial texture is imprinted on the surface. This type of leather is the most common in terms of pattern and color across all leathers. It has a less natural look than aniline or semi-aniline, but it is very resistant to spills and scratches, and therefore it requires less care than other types of leather. It is suitable for example, for sofas for families with children.

What happens in the tannery?

What happens in the tannery?

Tanning

This process, which takes about 48 hours, makes the hides stable and easy to work with. The hides acquire a grayish color.

Splitting

A 6 to 8 mm thick leather is split into two parts. The top part is known as grain leather, and the lower part - split leather. We use the splits to cover parts on furniture that are not seating and wear surfaces. Grain leather - the top part of the hide - is very durable and is used, for example, in the furniture industry, where there is a need for high durability.

Sorting

Final inspection of grain leathers is done manually. The leather is sorted by grain damage: the finest leathers with the least damage are turned into aniline or semi-aniline. Only 5% of leathers are turned into exclusive aniline leather. Please note that a semi-aniline leather can only be called a semi-aniline leather if the grain is intact. The leather is called corrected leather if the grain has been ground down before dyeing. Leathers with many marks are milled and corrected and turned into standard leather, which has embossed grain and no open pores at all - corrected leather, but still grain leather.

Through dyeing

All hides are dyed, thus obtaining the final base color.

Drying

The hides are stretched and dried in various ways depending on how they will be made.

Testing

The test of the final product is very important in order to determine the leather’s durability, flame retardant, lightfastness, dry friction, wet friction, sweat friction, finish adhesion, tear resistance, and the thickness of the leather. All these aspects are tested on each batch of finished leather. From rawhide to finished leather, it takes about 4 to 6 weeks.